22 April 2022 (11:56-UTC-07 Tango 06) 02 Ordibehest 1401/20 Ramadan 1443/22 Jia Chen 4720

“Supply chains are pivotal in the production of both military and civilian products and technologies. Our team looked at two questions; a: How do you assess the impacts of supply chain disruptions on the manufacturing bottom line and product availability to consumers, and b: How do you mitigate supply chain disruption and increase their ability to recover, particularly when the various secondary or tertiary contributors to a supply chain are poorly characterized?”-Igor Linkov, senior scientific technical manager for U.S. Army Engineer Research and Development Center’s (ERDC) Environmental Laboratory

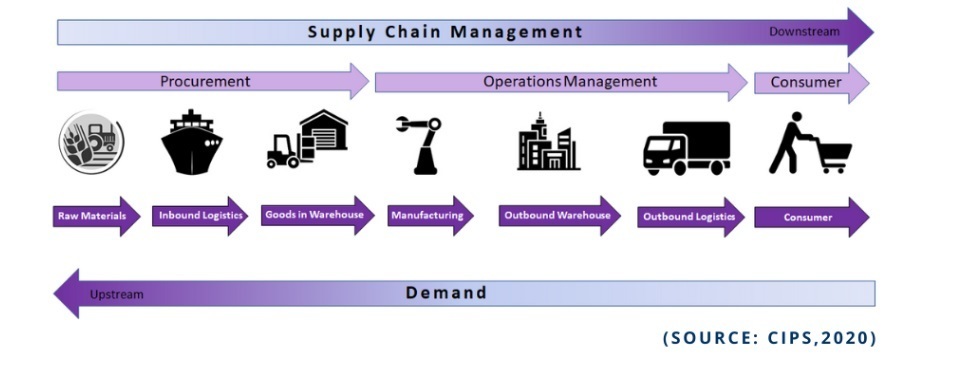

The U.S. Army inadvertently admitted that supply chain problems blamed on The Pandemic are actually because the global supply system became a ‘just-in-time’ system (based on the Japanese system) operated by A-I and robots, which has proven to be a failure when something unexpected like government pandemic mandates, or other catastrophes, strikes.

The Japanese just-in-time supply system has proven itself to be a failure time and time again, every time Japan experiences some kind of natural disaster. Yet, the globalized supply operation adopted the just-in-time system, along with A-I and robots, because it creates huge profits by supposedly reducing the need for massive warehouse operations, at least that is what was thought. Since governments began panicking over The Pandemic and implementing pandemic mandates, which directly affected the globalized supply system, it has been realized (ironically) that in order to deal with natural and human-made catastrophes the globalized just-in-time system needs even more warehouse operations than before the just-in-time system was adopted: “In both retail and manufacturing, we see businesses abandoning the dominant lean, Just-in-Time, low-inventory, procurement-led supply chain model. With increasing risk from events such as, Covid, Brexit, trade friction with China, flooded Taiwanese chip-makers, and the Suez Canal blockage, businesses are facing greater uncertainty and are looking to build resilience into their supply chains. And that means holding more inventory, which in turn puts further pressure on available warehouse space.”-Logistics Manager, 26APR2021

Concerned about being able to get the supplies it needs to produce its own Pandemic nano-vaccines, the U.S. Army’s ERDC-Environmental Laboratory studied how the current just-in-time supply chain could adversely affect nano-vaccine production: “We have tried to attract attention to the problem that in manufacturing nano-enabled products, supply chain operations are foundational logistical challenges that require careful governance. We tried to look at how supply chain works for nano-enabled products and use this as a way to illustrate the importance of resilience and efficiency in supply chains.”-Benjamin Trump, U.S. Army ERDC-Environmental Laboratory

Read the study for yourself: Resilience and efficiency for the nanotechnology supply chains underpinning COVID-19 vaccine development

Operation Jupiter: U.S. ARMY UPDATES PROGRESS ON NANO-SPONGE VACCINE, claims it to be 90% EFFECTIVE!

Pandemic Logistics Perfidy: SKYROCKETING USED CAR PRICES & INSURANCE RATES actually STARTED YEARS BEFORE THE SHORTAGES!

Pandemic Perfidy: LIFE INSURANCE INDUSTRY & MILITARY REPORT MASSIVE INCREASE IN ‘NON-PANDEMIC’ DEATHS, BLAME THE ‘NEW’ UN-WHO ICD-10-CM CODES?

Operation Jupiter 2015: A SMALL PART OF A LARGER MILITARY OPERATION SPREADING DISEASE AT A HOSPITAL NEAR YOU!